Professor Yu-Lin Kuo of Taiwan Tech develops advanced energy storage battery to enhance safety and energy autonomy.

Amid global energy transitions and pressure to reduce carbon emissions, renewable energy not only needs to be sufficient, but also green and safe. Professor Yu-Lin Kuo, Distinguished Professor in the Department of Mechanical Engineering at Taiwan Tech, leads a team that has developed a vanadium redox flow battery (VRFB) using plasma technology. The battery features a low-carbon production process, long lifespan, and high safety, with the potential to help both businesses and households achieve energy self-sufficiency. If widely adopted, the technology could not only enhance energy storage safety but also address concerns highlighted by a recent lithium battery fire at a South Korean government data center.

Professor Yu-Lin Kuo and his team at the “2025 Net-Zero Emissions Technology International Competition”

Currently, the most common energy storage technologies on the market are lead-acid batteries and lithium-ion batteries. Lead-acid batteries are low-cost but contain lead and acidic electrolytes, which pose environmental pollution and recycling challenges. Lithium-ion batteries, on the other hand, offer high energy density and compact size, but under high temperatures, overcharging, or structural damage, they can experience thermal runaway, potentially leading to fires or explosions. These safety concerns correspond closely to a recent incident in South Korea, where a lithium-ion battery caused a fire during a UPS (uninterruptible power supply) relocation at a government data center. In such cases, inadequate safety measures can result in extremely serious consequences, including combustion and explosions.

In this context, the safety improvements achieved by Professor Yu-Lin Kuo’s research team at Taiwan Tech, using atmospheric plasma processing to fabricate flow battery electrodes, are particularly noteworthy. The team employs room-temperature, atmospheric-pressure plasma technology to uniformly deposit various metal oxides as catalysts for energy storage reactions onto carbon materials. This process requires no acidic solutions, produces no chemical wastewater, and does not need high-temperature equipment or vacuum chambers. The method is simple, environmentally friendly, and safe, enhancing energy storage efficiency while significantly reducing both carbon footprint and manufacturing risks. Professor Yu-Lin Kuo emphasized, “Batteries produced through this method almost entirely avoid energy-intensive processes, naturally lowering the carbon footprint, and are less likely to be subject to carbon taxes.”

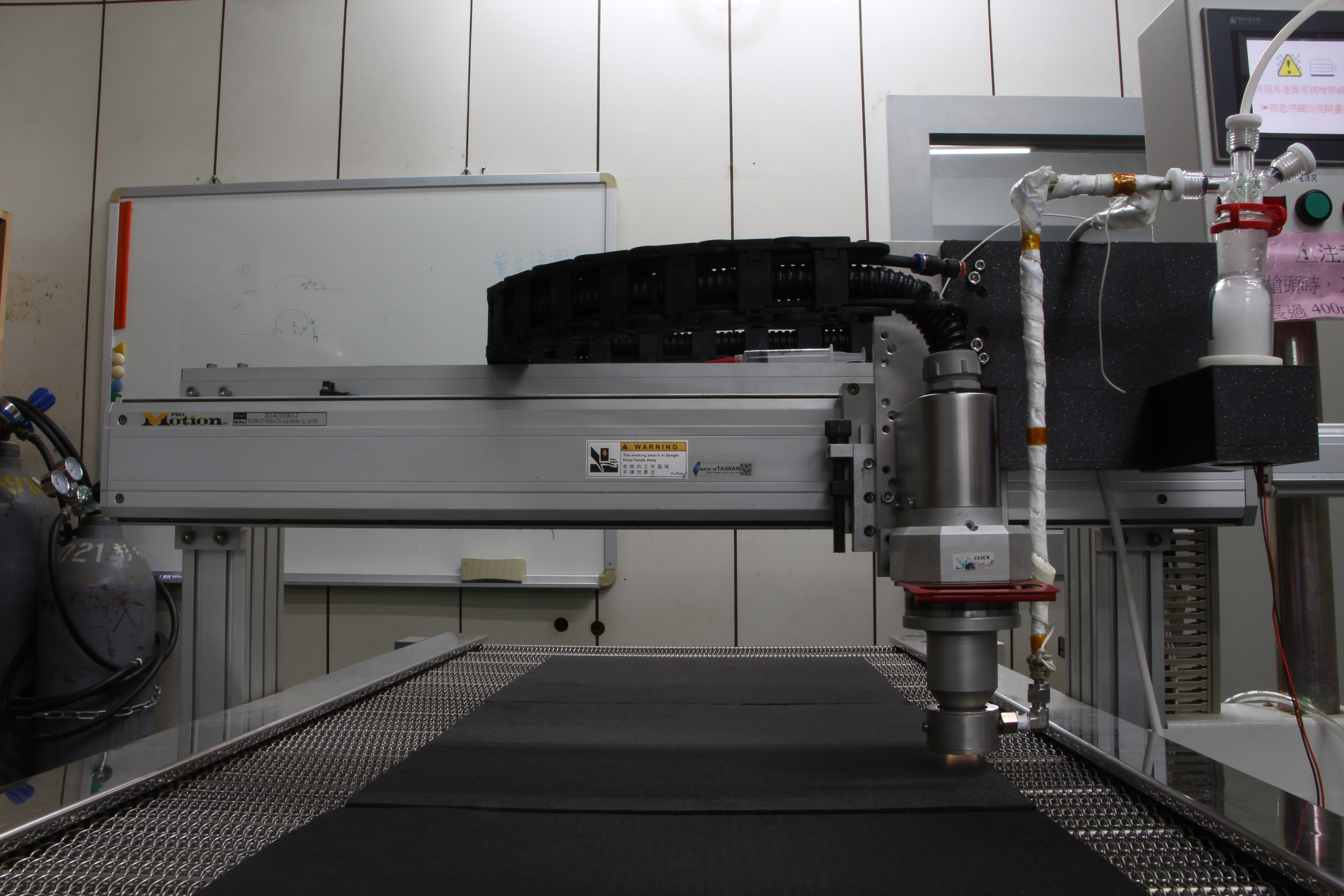

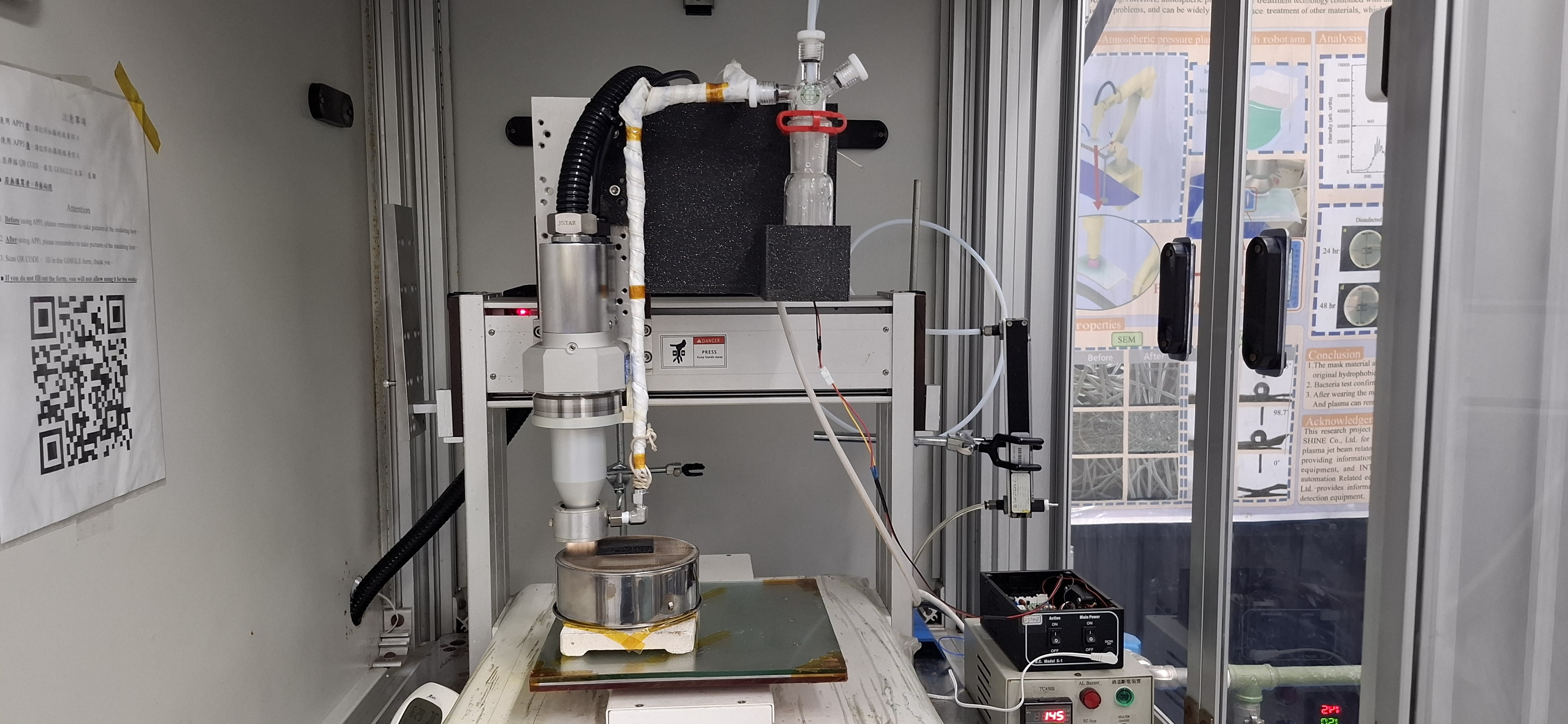

The team used room-temperature, atmospheric-pressure plasma technology to uniformly deposit various metal oxides as catalysts for energy storage reactions onto carbon materials. Shown here is the large-scale jet-type atmospheric-pressure plasma coating equipment.

Additionally, the team stated that this vanadium redox flow battery can be used in parallel with solar and wind energy systems, functioning like an “electric water tower” that stores electricity during off-peak periods and releases it during peak demand, helping businesses and households achieve energy self-sufficiency. Ahmad Nur Riza, a doctoral student leading the team’s research, highlighted that compared with lithium-ion batteries, it offers advantages such as reliance on more abundant materials with stable supply, reduced risk of fire or explosion, longer cycle life, excellent scalability, and flexible sizing. Professor Yu-Lin Kuo emphasized, “Beyond high-efficiency battery research in academia, the most important achievement is safe, green energy storage technology that can truly be implemented in homes and businesses.”

The team used room-temperature, atmospheric-pressure plasma technology to uniformly deposit various metal oxides as catalysts for energy storage reactions onto carbon materials. Shown here is the jet-type atmospheric-pressure plasma coating equipment.

Professor Yu-Lin Kuo emphasized, “As the world becomes increasingly dependent on data centers and power infrastructure, the safety and stability of energy storage systems form the baseline.” The team is currently collaborating with Taiwanese manufacturers on battery mass-production development and the creation of a lifespan monitoring system. They are also actively planning to integrate AI and big data analytics to establish a comprehensive battery aging monitoring system, capable of predicting potential faults and optimal maintenance schedules.

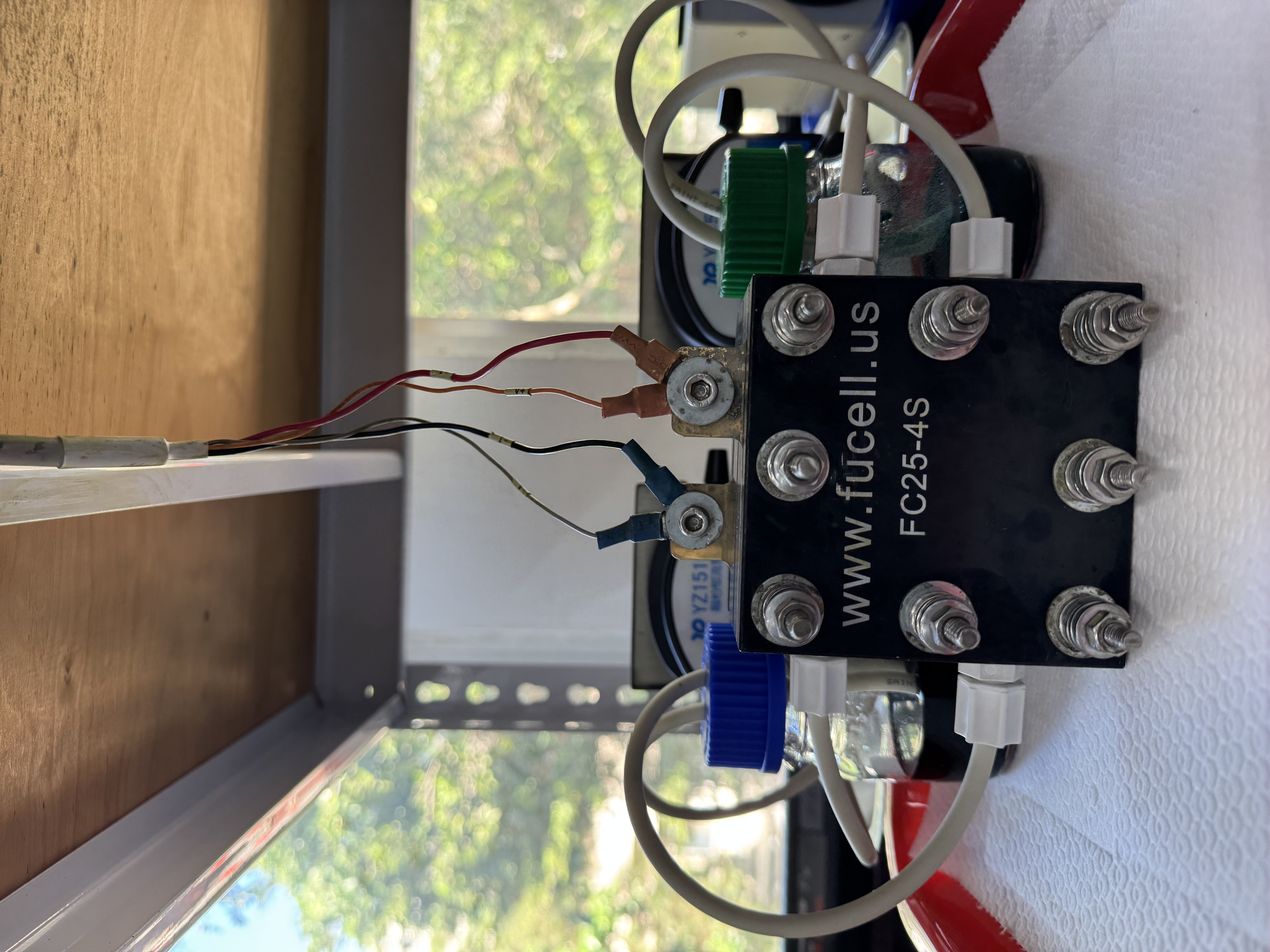

Professor Yu-Lin Kuo leads a team that has developed a vanadium redox flow battery using plasma technology. Shown here is a single-cell vanadium redox flow battery used to test the effects of electrode materials on electrochemical performance.

In addition, this technology has been published in the Q1 (top 25%) journal Applied Surface Science and received awards at the “2025 Net-Zero Emissions Technology International Competition,” organized by the TECO Technology Education and Culture Foundation and National Taiwan University. Professor Yu-Lin Kuo emphasized that this represents not only a scientific breakthrough but also an opportunity for Taiwan to play a more significant role in the global energy arena: “True green energy is not just about reducing carbon - it is about enabling everyone to become an energy producer.”

Doctoral student Ahmad Nur Riza demonstrates the experimental procedure.