Taiwan Tech Team wins top honors for AI-Powered Smart Rail System at Makerthon.

At the 2025 Makerthon, students from Taiwan Tech achieved outstanding performances. Sophomores Yung-Hsiang Yu, Meng-Hsuan Wu, and Chin-Hsuan Yang from the International Bachelor Program in Global Development Engineering (Mechanical Engineering track) won the competition's highest honor - the Grand Jury Prize - with their project "Decarbonizing Detection: Miniature Onboard Rail Inspection Module". Meanwhile, junior from Department of Electrical Engineering, Ting-Hsu Wu, and students from Department of Comouter Science and Information Engineering, Jui-Ming Yao and Ping-Cheng Hsieh were also recognized with an Honorable Mention for their collaborative project, "Urban Smart Edge Computing System".

This year's Makerthon centered on the United Nations Sustainable Development Goals (SDGs), challenging participants to develop innovative, low-carbon public transportation solutions. The award-winning rail inspection module can be mounted beneath regional train cars, using ultrasonic sensors to monitor track gauge, accelerometers to detect elevation and alignment shifts, and AI-based image recognition to identify cracks or anomalies. Paired with an IoT platform, the system enables real-time data transmission and GPS tracking, significantly improving the efficiency and frequency of rail maintenance.

Yung-Hsiang Yu (center), Meng-Hsuan Wu (right), and Chin-Hsuan Yang (left), sophomores in the Mechanical Engineering track of Taiwan Tech's International Bachelor Program in Global Development Engineering, won the Grand Jury Prize at the Makerthon with their project "Miniature Onboard Rail Inspection Module".

Team Leader Yung-Hsiang Yu, an avid railway enthusiast, explained that traditional diesel-powered inspection trains must cover Taiwan's 1,065 kilometers of railway at least four times a year. The resulting carbon emissions and air pollution have a significant environmental impact. By integrating the inspection module into regular passenger trains, emissions from dedicated inspection runs could be dramatically reduced. At the same time, inspection frequency could be increased, helping lower energy loss and safety risks caused by faulty tracks. The team drew on both their academic knowledge and hands-on experience from the Robotics Club, employing skills in computer-aided design, laser cutting, 3D printing, and image recognition to develop a practical, low-carbon rail inspection module with strong market potential.

As first-time participants, the team initially joined the competition simply to gain experience in hands-on prototyping and collaborative challenges during their sophomore year. Before settling on the rail inspection module as their core concept, they went through heated internal debates. But it was through this intense process of reasoning and iteration that their project took shape—ultimately winning the top prize. Meng-Hsuan Wu, who was responsible for AI training and image recognition, said the experience revealed the endless nature of learning. "There's always something to refine and optimize - perfection doesn't exist." Chin-Hsuan Yang, who handled control board wiring and hardware integration, shared that the competition pushed him beyond his comfort zone: "I'm usually more passive and content, but this challenge made me realize that trying something new isn't so scary. It gave me new motivation and direction in my university life."

After extensive discussion, debate, and feasibility assessment, Yung-Hsiang Yu (right), Meng-Hsuan Wu (center), and Chin-Hsuan Yang (left) chose to focus on a cost-saving solution -developing a rail inspection module - as their final project for the competition.Photo courtesy of the event organizers.

The "Miniature Onboard Rail Inspection Module" can be directly mounted beneath regional train cars. It uses ultrasonic sensors to measure track gauge and accelerometers to detect track alignment and vertical irregularities. Integrated with AI-powered image recognition, the system can identify cracks and anomalies on the rails. Data and GPS coordinates are transmitted in real time via an IoT platform, significantly enhancing inspection frequency and maintenance efficiency.

To promote the spirit of open innovation, the team has open-sourced both the module's design files and its edge computing programs, hoping to foster future industry-academia collaboration and accelerate real-world application of the technology. They also expressed their sincere gratitude to Assistant Professor Tsung-Ho Hu from the College of Engineering, whose guidance outside of class - sharing expertise in mechanical systems, civil engineering, and industry practices - greatly inspired their creative thinking and practical direction.

To promote the spirit of open innovation, the team has open-sourced the module's design files and edge computing software, hoping to engage in future industry-academia collaboration and drive the practical application of their innovative technology.

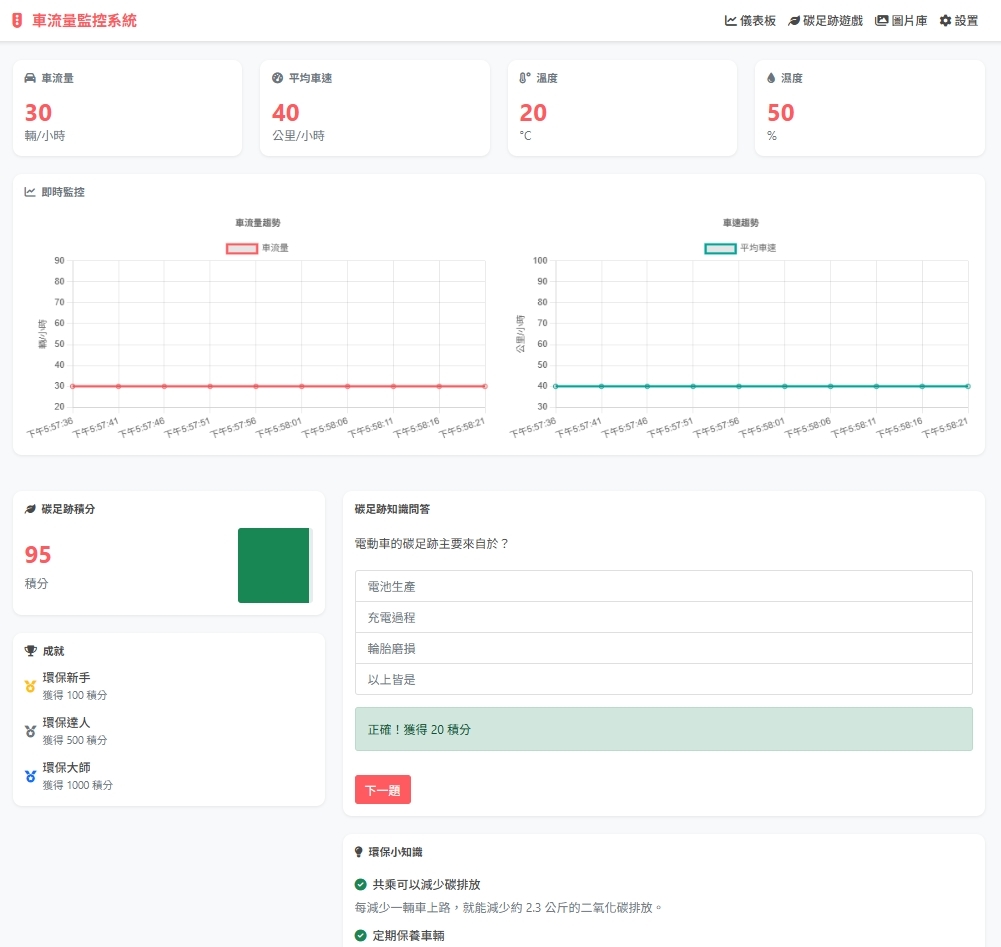

Another team awarded Honorable Mention was composed of Ting-Hsu Wu, a junior in Department of Electrical Engineering, along with students students from Department of Comouter Science and Information Engineering, Jui-Ming Yao and Ping-Cheng Hsieh. Wu and Yao, both seasoned participants in the Makerthon for three consecutive years, teamed up with first-time competitor Hsieh to take first place in the regional round and later secure an Honorable Mention at the national finals. Their project, "Urban Smart Edge Computing System", integrates surveillance cameras with AI-powered image recognition to monitor traffic flow in real time. The system adjusts traffic signal durations dynamically via an analytics platform, effectively easing congestion, reducing idling, and lowering carbon emissions - moving toward the dual goals of smart transportation and environmental sustainability.

Ting-Hsu Wu (front row, first right), a junior in Department of Electrical Engineering, together with students from Department of Comouter Science and Information Engineering Jui-Ming Yao (second row, first right) and Ping-Cheng Hsieh (back row, first right), developed the "Urban Smart Edge Computing System", which received an Honorable Mention at the Makerthon.

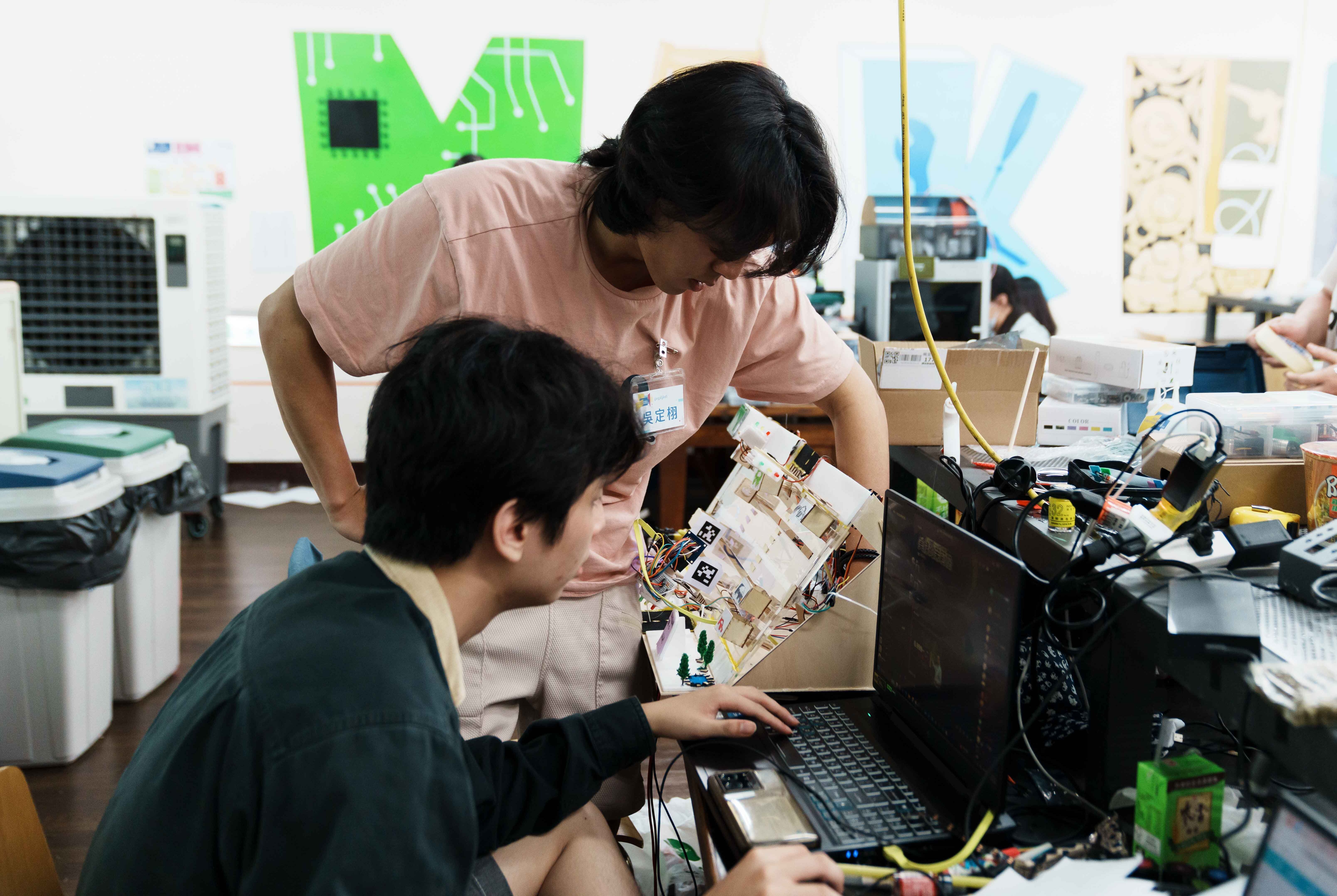

Ting-Hsu Wu (back) and Ping-Cheng Hsieh (front) were primarily responsible for training the visual recognition model and developing the analytics platform, enabling the system to detect traffic flow and adjust signal timing - helping to ease congestion, reduce idling, and lower carbon emissions. Photo courtesy of the event organizers.

The team also proposed a "Dynamic Road Barrier Concept", inspired by the Barrier Transfer Machine technology commonly used in Europe. Ting-Hsu Wu explained that, for example, during peak holiday travel periods such as the Lunar New Year, southbound traffic often far exceeds northbound volume. If lane allocations could be adjusted temporarily, it would help alleviate congestion and improve traffic flow during peak hours.

Beyond technical applications, the team also addressed the human dimension of transportation issues. They developed an eco-education website featuring quizzes and a point-based reward system to encourage the public to learn about sustainability and adopt low-carbon travel habits. By using a "soft engagement" approach, the team aimed to raise environmental awareness and promote sustainable behavior at its roots.

Reflecting on the competition, the team acknowledged it was full of challenges. Team leader Ting-Hsu Wu noted that this year's national final was significantly tougher than expected. During the ideation phase, they frequently hit roadblocks and often found themselves critiquing one another's proposals. "Struggling to make things work is the norm", he said, "which is why having multiple backup plans and solving problems as they arise is essential". He emphasized that stress management and knowing when to pivot are key skills in hands-on competitions.

Jui-Ming Yao shared that the experience greatly improved his time management and decision-making skills. On the technical side, the most difficult part was integrating multiple system functions and training the AI model. During the final stretch, the team slept only an hour or two a night, pushing themselves to their mental and physical limits. Despite the exhaustion, they remain determined to compete again next year - this time with a more refined, feasible, and complete project worthy of the Grand Jury Prize.

The team also developed an environmental education website that promotes sustainability through interactive learning. By incorporating knowledge-based quizzes and a point-reward system, the platform encourages the public to actively engage with environmental topics and adopt low-carbon travel habits - advancing the concept of sustainability from the ground up.