Taiwan Tech and Rishiki Corporation launch 3D imaging lab for high-precision, non-destructive testing.

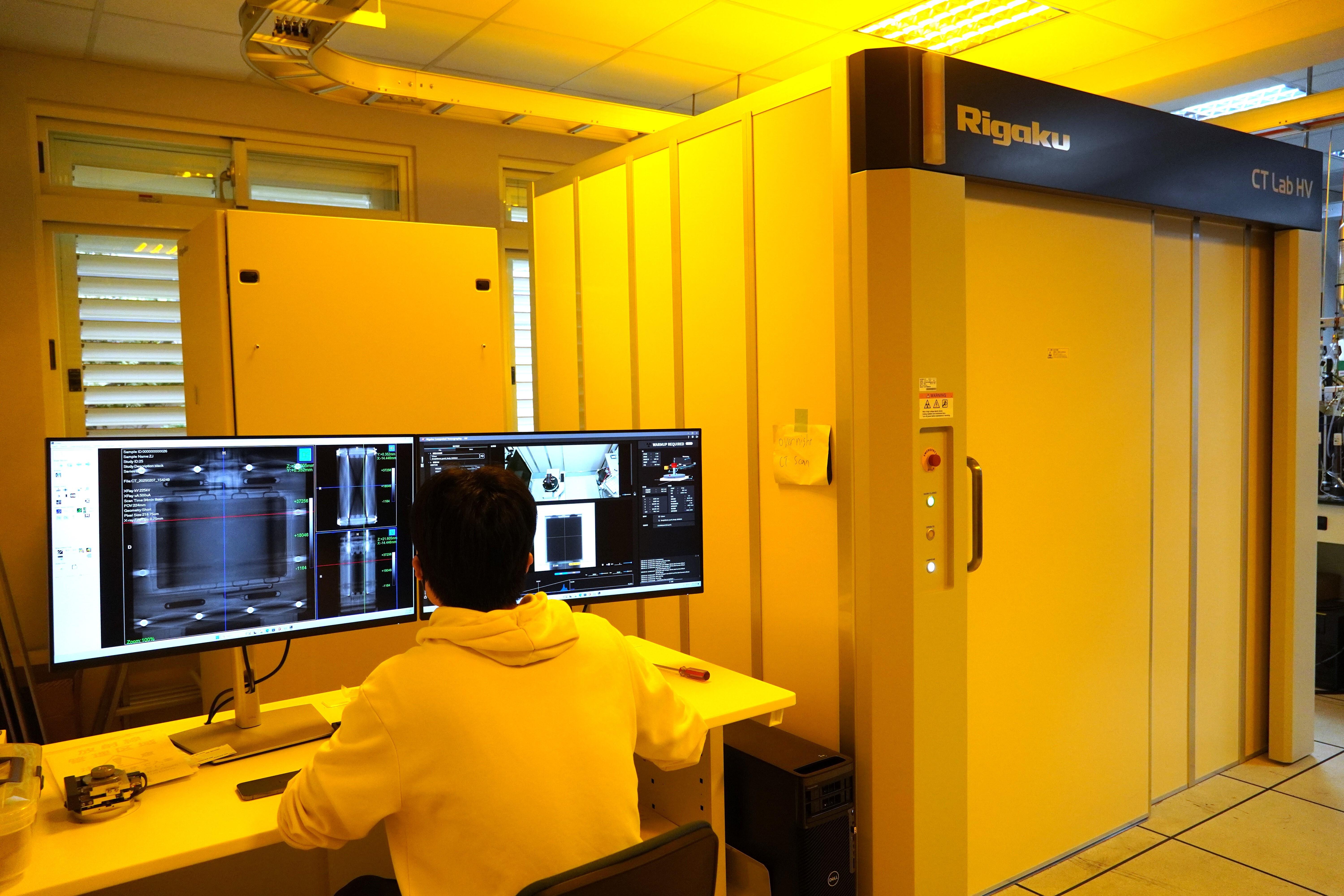

With the rapid development of technology, 3D imaging reconstruction has become a crucial tool in materials science and advanced manufacturing, with widespread applications in semiconductor packaging, advanced material development, and precision industrial inspection. To promote high-precision materials research and packaging technology development, Taiwan Tech has partnered with Rigaku Corporation, a provider of X-ray analysis solutions, to establish the “Frontier Materials and Advanced Packaging 3D Imaging Reconstruction Development Laboratory” on the 27th. The collaboration aims to enhance Taiwan Tech’s research capabilities in advanced manufacturing by utilizing cutting-edge non-destructive testing and 3D imaging reconstruction technologies.

Group photo at the unveiling ceremony.

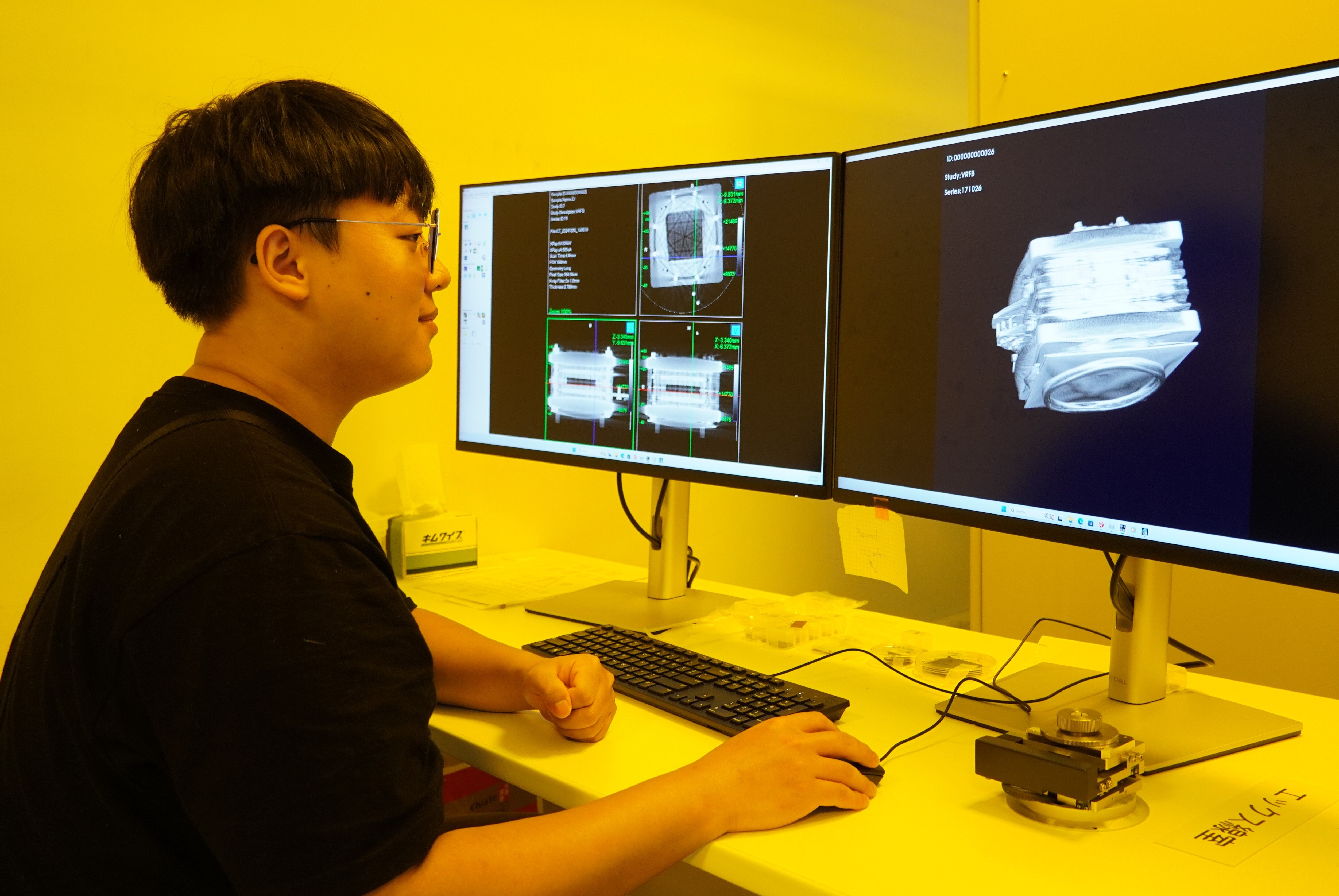

Taiwan Tech uses the latest industrial-grade 3D X-ray computed tomography (XCT) and analysis system from Rigaku Corporation for advanced packaging and materials analysis. This allows researchers to gain a deeper understanding of the structures of advanced packaging and materials at the sub-micron scale, enabling more detailed defect detection, which supports technological innovation and product optimization.

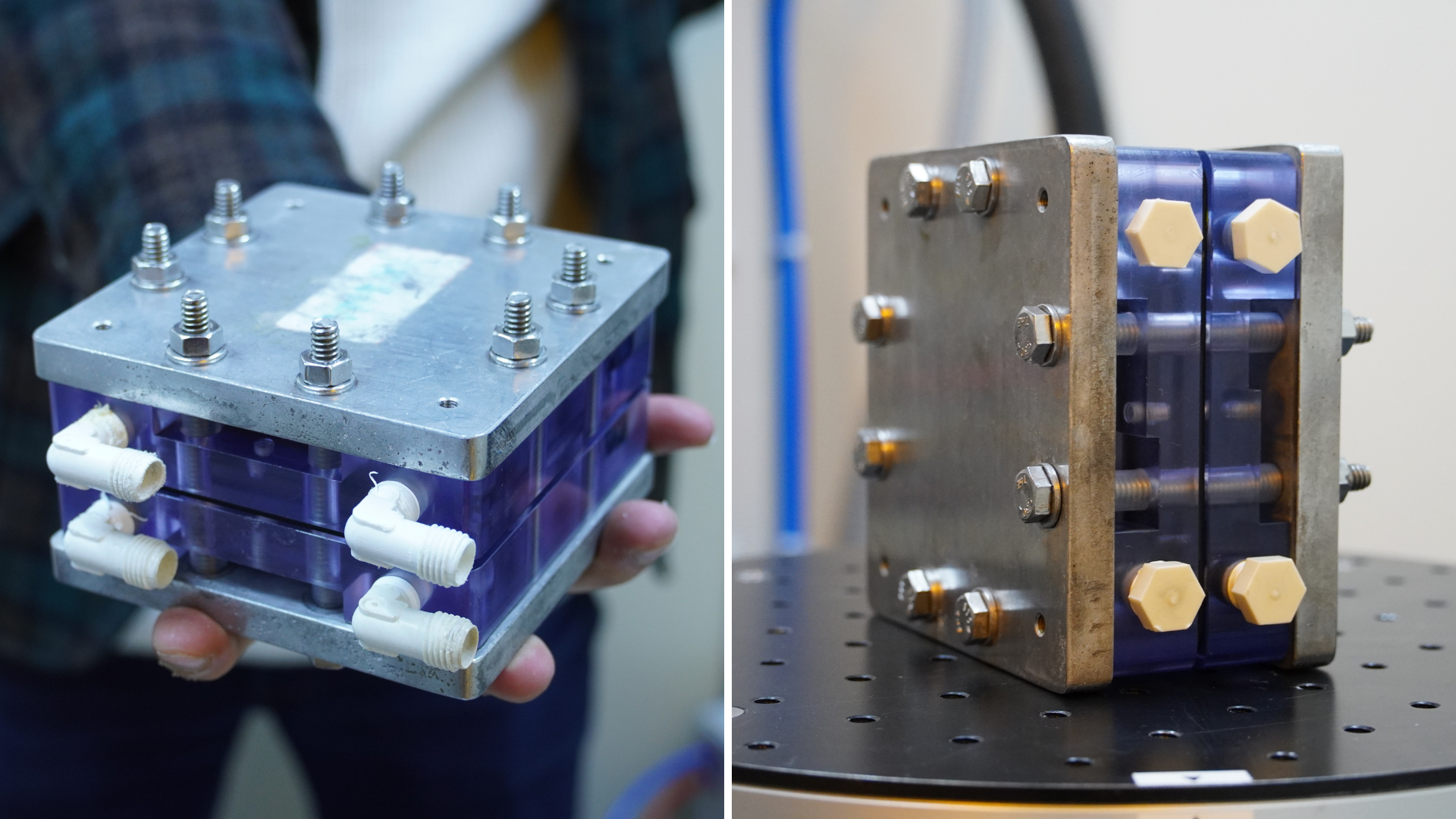

The 3D X-ray computed tomography system is designed for industrial inspection and failure analysis. It can quickly collect complete 3D structural information of a sample within half an hour, analyzing impurities, pores, cracks, and their size and location. With spatial resolution as high as 3 microns, it also allows for a flexible selection of sample sectioning positions and angles for defect analysis. For example, researchers can analyze the distribution of chemicals or electrolytes inside a liquid flow battery or lithium battery without disassembling the device, helping to evaluate the safety and stability of the product.

Taiwan Tech’s Advanced Manufacturing R&D Center has independently developed a flow battery and utilized the 3D X-ray computed tomography system for analysis. By integrating the R&D and testing processes, the overall research efficiency is significantly enhanced.

The 3D X-ray computed tomography system supports samples with a maximum diameter of 600 mm and a height of 1200 mm. In the future, it will serve Taiwan's small and medium-sized enterprises, providing technical support for product analysis, defect detection, and quality control.

The “Frontier Materials and Advanced Packaging 3D Imaging Reconstruction Development Laboratory” is not only an academic research base but will also serve Taiwan's small and medium-sized enterprises in the future. It will provide technical support for product analysis, defect detection, and quality control, helping businesses identify problems, generate inspection reports, and offer solutions. This will enable industries to optimize product quality and production processes through precise non-destructive analysis techniques.

Additionally, the laboratory will serve as a training ground for PhD students and researchers. By operating advanced instruments and developing solutions, they will accumulate hands-on experience, improve their skills through practical applications and research exchanges, and further promote talent development and industry-academia collaboration. This will contribute to the cultivation of advanced technical talent and drive industry innovation.

3D X-ray computed tomography can collect complete 3D structural information of a sample within half an hour, analyzing impurities, pores, and cracks in terms of location and size. It also allows for a flexible selection of sample sectioning positions and angles for defect analysis.

The “Frontier Materials and Advanced Packaging 3D Imaging Reconstruction Development Laboratory” also serves as a talent training ground, allowing PhD students to accumulate hands-on experience. Through practical applications and research exchanges, they can enhance their skills, further promoting talent development and the synergistic effect of industry-academia collaboration.

Jun Kawakami, President and CEO of Rigaku Corporation, expressed high expectations for the collaboration, stating that they will continue to deepen and expand the scope of their partnership to advance and apply high-energy X-ray computed tomography technology.

Taiwan Tech President Jia-Yush Yen also expressed gratitude to Rigaku for providing top-tier equipment, allowing Taiwan Tech to utilize the most advanced testing technologies in its research and create more fruitful academic and industrial applications. Dr. Ming-Jyh Chern, Dean of the College of Engineering, stated, “This collaboration will significantly enhance Taiwan Tech’s analytical and research capabilities in advanced manufacturing. The laboratory will also actively serve advanced materials research across various fields in Taiwan, while simultaneously establishing a high-precision database and incorporating AI technology to develop real-time analysis software, improving both precision and efficiency, and building a digital platform for materials research and analysis.”

As technology advances and industrial demands rise, the importance of 3D imaging reconstruction technology becomes increasingly prominent. This strategic collaboration between Taiwan Tech and Rigaku will accelerate technological development in materials science and advanced manufacturing. Moving forward, both parties will continue to deepen their cooperation, expand the scope of applied research, and, through industry-academia collaboration, promote Taiwan’s high-tech industry’s integration with international standards, establishing a world-class materials science and packaging technology R&D hub.

Speech by Taiwan Tech President Jia-Yush Yen.

Speech by Jun Kawakami, President of Rigaku Corporation.