Chair Professor Yu-Chung Tsao from Taiwan Tech: advancing smart manufacturing and logistics.

Professor Yu-Chung Tsao, Dean of the School of Management and Director of the Artificial Intelligence Operations Management Research Center at Taiwan Tech, in response to changing global conditions and industry challenges, proposed a supply chain resilience assessment framework and indicators. He led a research team in collaboration with the Industrial Technology Research Institute (ITRI) to develop the “Supply Chain Resilience Improvement Health Check Service Platform”. Over 100 companies have participated in the resilience evaluation, with industries served including electronics, precision machinery, and consumer chemicals. For this resilience assessment platform and other achievements that combine academia and practice, he was awarded the “2024 Delta Young Technology Scholar Award”.

Taiwan Tech Professor Yu-Chung Tsao (second from left) with his laboratory students.

Taiwan Tech Professor Yu-Chung Tsao (right) was awarded the “2024 Delta Young Technology Scholar Award” pictured with Delta Electronics Chairman Ping Zheng (left).

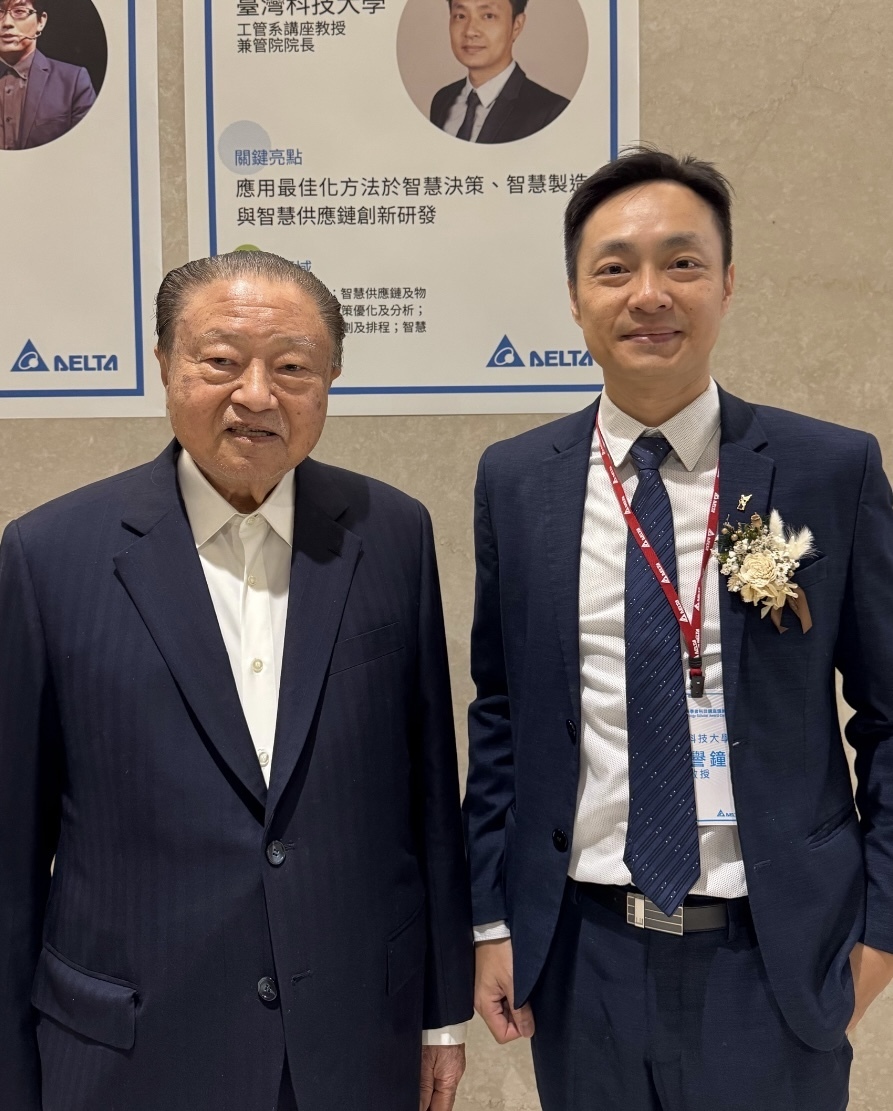

Taiwan Tech Professor Yu-Chung Tsao (right) was awarded the “2024 Delta Young Technology Scholar Award”, pictured with Delta Electronics Founder Chonghua Cheng (Bruce C.H. Cheng) (left).

The “Supply Chain Resilience Improvement Health Check Service Platform” is a system centered around an assessment tool, with its core being the supply chain resilience assessment framework proposed by Professor Yu-Chung Tsao. Through a questionnaire survey, it provides a comprehensive evaluation of various dimensions of supply chain resilience for companies. With the platform’s health check, companies can assess their performance rankings in five key capabilities: digital, analytical, decision-making, collaboration, and sustainability. The data-driven insights further enhance the stability and competitiveness of supply chains. Excitedly, Professor Tsao shared that the “Supply Chain Resilience and Smart Logistics Management Assessment” is a highly advanced indicator that can be applied across industries to help companies conduct health checks for their supply chain and production management decisions. Future plans include integrating AI technology to optimize the evaluation model further, helping companies better understand and improve the five key capabilities to enhance supply chain resilience.

Previously, Professor Tsao had led Taiwan Tech graduate students to significant achievements in multiple award-winning projects. He shared that his research on smart manufacturing covers both on-site and off-site applications. For example, in the off-site application of the “Supply Chain Resilience Improvement Health Check Service Platform” and, on-site, his research focuses on using robotic arms to solve issues related to stacking different-sized boxes, optimizing the pallet usage efficiency in logistics and storage. This overcomes the limitations of traditional equipment, which can only handle items of the same size, and takes into account complex factors like the center of gravity and volume, achieving optimal and intelligent logistics operations.

Regarding the application of AI technology across various industries, he mentioned that his team had developed a “Fashion Designer Recommendation System” that analyzes publicly available information on popular market styles to predict the potential of fashion trends. Additionally, through the use of AI methods, they have assisted companies in solving practical problems in demand forecasting, bidding predictions, scheduling, personnel assignments, defect detection, quality forecasting, layout optimization, material combinations, transportation, and inventory optimization.

In addition to practical applications, Professor Tsao also emphasized the importance of strong industry-academia collaboration. He pointed out that the core value of such collaborations lies in identifying the key issues that affect industries, requiring years of accumulated experience. Currently, Taiwan Tech’s School of Management and the Artificial Intelligence Operations Management Research Center collaborate with several companies, including Taipower, Chunghwa Post, Uni-President, FamilyMart, and the Logistics Association, to tailor training programs for industries.

Looking back on his research journey, Professor Tsao candidly mentioned that the challenge in industry-academia collaborations is discovering and defining core problems, which demands substantial experience. He also emphasized that it is these challenges that motivate researchers to find solutions. Moving forward, he hopes to continue making breakthroughs in smart manufacturing, logistics, and AI applications, and integrate the United Nations’ Sustainable Development Goals (SDGs) to enhance the sustainability evaluation details of the Supply Chain Resilience Improvement Health Check Service Platform, further expanding the influence of both academic and practical fields.

Taiwan Tech Professor Yu-Chung Tsao (center) with his laboratory students.