Taiwan Tech’s Professor Fu-Ming Wang wins Y. Z. Hsu Science Award for advancing green energy and reducing lithium battery fire risk.

To achieve the goal of net-zero carbon emissions by 2050, the government has proposed strategies targeting energy, industry, and daily life. Among these, lithium batteries play a crucial role in electronic devices, electric vehicle batteries, and energy storage systems. However, incidents of lithium battery fires and explosions are still a concern. Professor Fu-Ming Wang, a distinguished professor at Taiwan Tech’s Graduate Institute of Applied Science and Technology, has dedicated 20 years to researching batteries and organic materials. By adding a newly developed oligomer additive to the cathode material of lithium batteries, he has significantly reduced the risk of fires and explosions, while maintaining battery performance and longevity. His work earned him the 2024 Y. Z. Hsu Science Award in the Green Technology category.

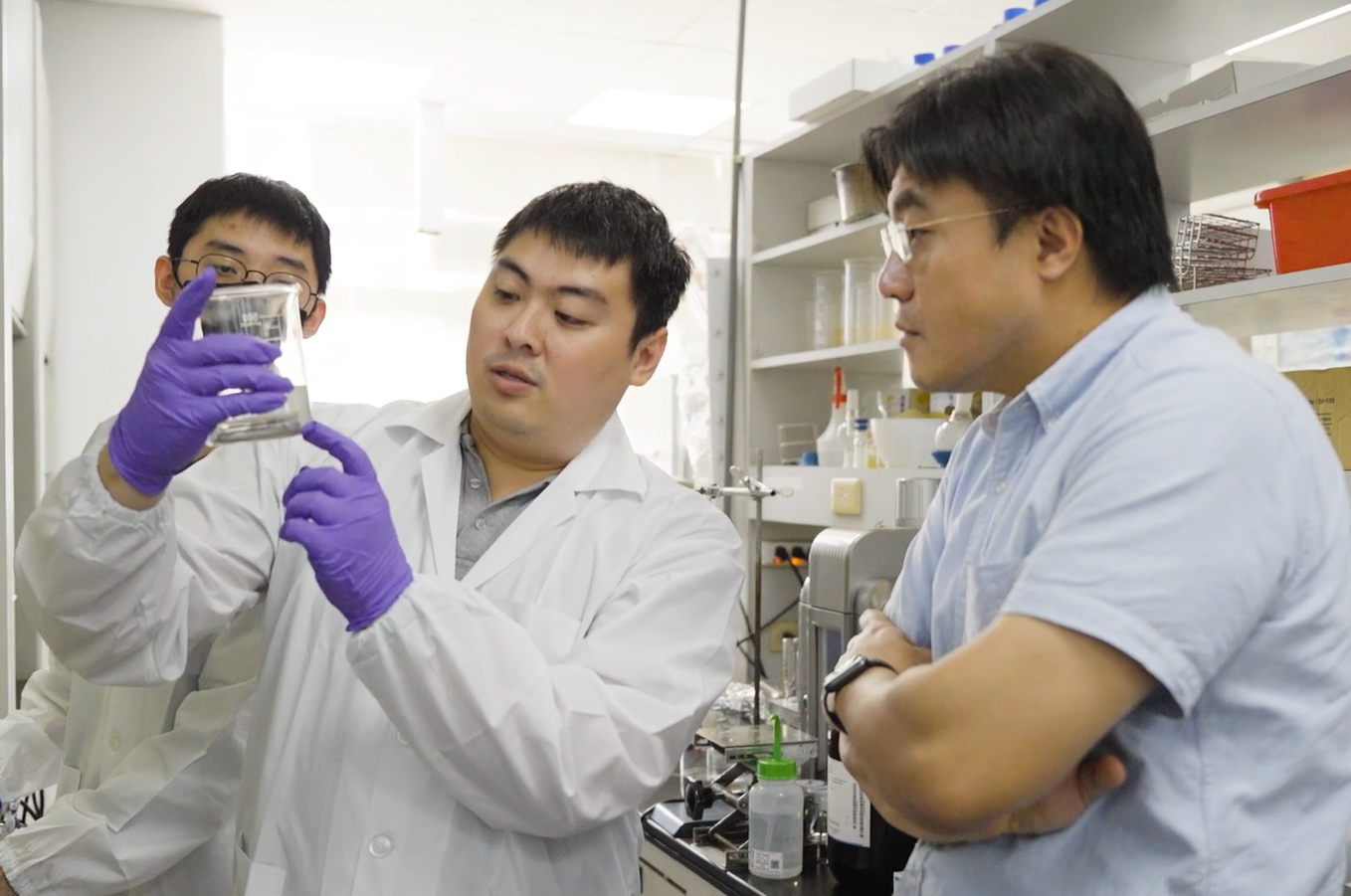

Taiwan Tech Distinguished Professor Fu-Ming Wang (3rd from left) developed a “Lithium Battery Cathode Material Preparation Method”, winning the 2024 Y. Z. Hsu Science Award.

Professor Fu-Ming Wang explained that while lithium batteries are currently the most energy-dense type of battery, enhancing their safety without compromising performance is a challenging task. He likens this balance to a seesaw: “If you want better safety, performance may drop; if performance and efficiency improve, the risk of use increases”. The core of his research on the “Lithium Battery Cathode Material Preparation Method” is finding a way to balance safety and performance.

By using an additive, Professor Wang has developed a method that creates an inert membrane structure on the surface of active materials within the battery, preventing the reduction of trivalent or tetravalent nickel ions to divalent nickel ions in the cathode. This stabilizes the chemical reactions inside the battery, effectively addressing the safety concerns of lithium batteries under high temperatures and voltages. The technology not only ensures safety but also extends battery life while maintaining performance. Although this method increases raw material costs by about 3% to 5% per kilogram, it significantly boosts the success rate of safety tests, achieving a reasonable balance between cost and safety, which has made it highly favored by the industry.

Professor Fu-Ming Wang (right) and his research team have dedicated years to studying ways to reduce the risks of lithium battery use and extend their lifespan.

Lithium batteries are widely used in energy storage technologies, such as in storage cabinets or uninterruptible power systems, and are particularly critical for semiconductor factories that operate 24/7. In these settings, lithium batteries ensure stable operations. These storage systems are typically idle but are activated during power outages or electrical failures. As a result, industries using these systems have strict safety requirements for lithium batteries and continue to invest in their technological improvements and upgrades.

Despite these advancements, Professor Fu-Ming Wang acknowledges that lithium batteries cannot be 100% safe. Current technologies aim to minimize risks or extend the escape time in the event of a battery fire or explosion. He emphasized that the ideal scenario would be for lithium batteries to fail without causing fire or explosion-simply losing function in a safe and controlled manner, allowing the battery to “quietly and gracefully end its life”.

Wang’s “Lithium Battery Cathode Material Preparation Method” has been patented in Taiwan, the United States, and China, and is now used by several lithium battery manufacturers. This includes applications in various Samsung mobile phones and tablets, where Wang’s technology enhances battery safety, longevity, and performance. Taiwan Tech’s research team is also working with Supreme Electronics Co., Ltd., setting up a pilot production and verification lab at the university’s Hsinchu branch. They are focused on improving lithium battery technology for electric vehicles, with plans for broader application in the electric vehicle market in the future.

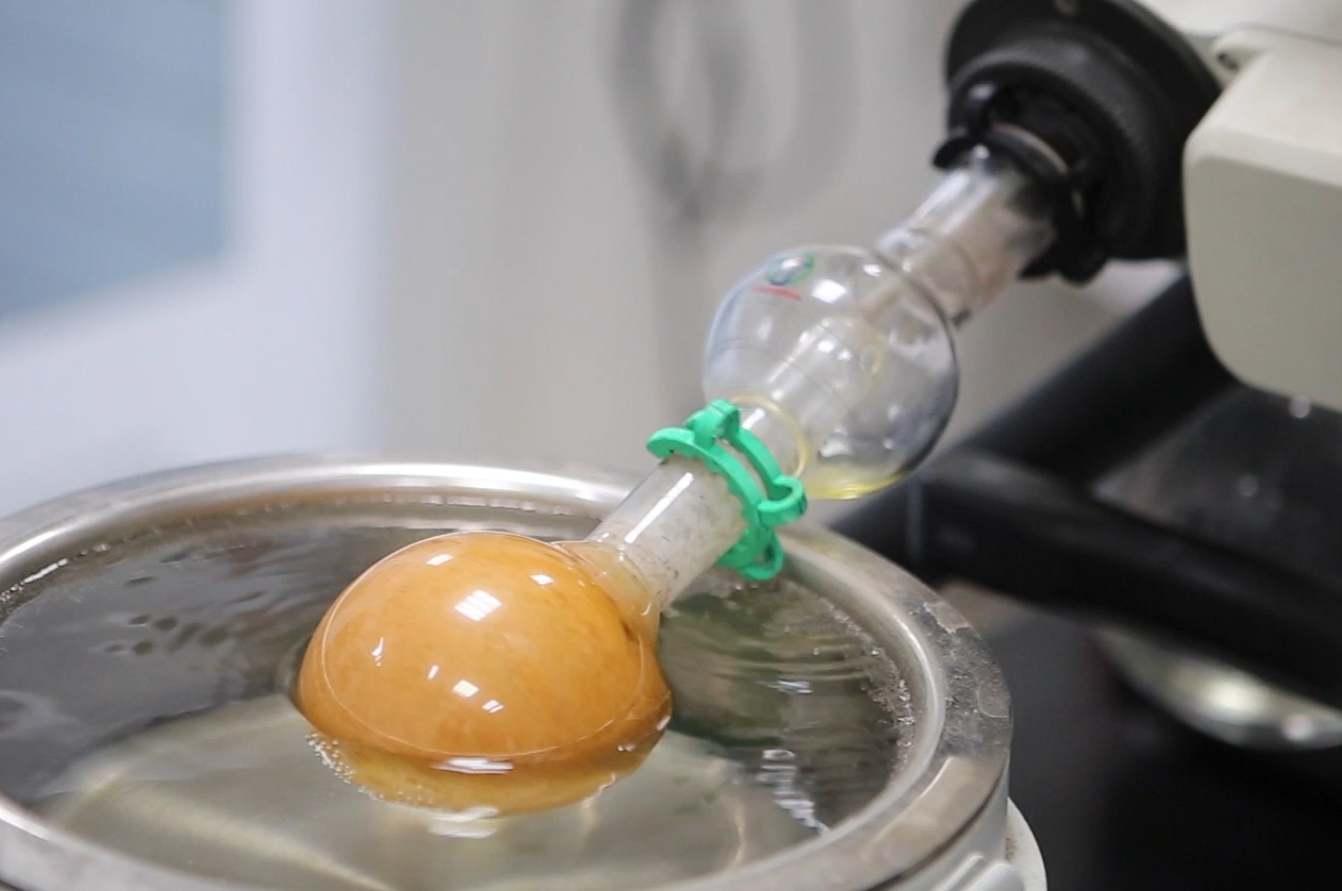

Professor Fu-Ming Wang has developed a new oligomer additive for lithium battery cathode materials, which reduces the risk of battery fires and explosions while maintaining both performance and lifespan.

“My research topics are driven by industry challenges”, says Professor Fu-Ming Wang, emphasizing the close collaboration between academia and industry to align research outcomes with market needs. Through such partnerships, he is able to conduct more in-depth analyses and evaluations. For example, lithium batteries are tested in various power systems, with manufacturers providing feedback on which system best suits the specific battery. This feedback loop allows for continuous refinement and the development of new technologies, creating a win-win situation.

Looking ahead, Professor Wang’s research will focus on green and sustainable technologies. While producing lithium batteries requires the use of heavy metals like nickel and manganese, he is exploring ways to incorporate green energy materials into battery packaging and external components. He is also researching alternative technologies, such as CO2 batteries and eco-friendly organic polymer batteries, to make battery production and recycling more environmentally friendly.

As lithium battery technology continues to evolve rapidly, Professor Wang also aims to assist in the development of regulations that ensure the safety of these batteries. His goal is to contribute to the industry’s technical advancements and support the global promotion and application of green technologies.

Professor Fu-Ming Wang uses a button cell charge-discharge tester to analyze the reactions of lithium batteries under changes in the cathode material.