Taiwan Tech cultivates 3D printing startups to help design enthusiasts fulfill their dreams.

While 3D printing has become popular in recent years, many still associate it with limited, small-scale production rather than mass printing. However, Taiwan Tech’s business incubation center has helped the startup “Freenity” break this barrier, enabling it to become a 3D printing company capable of mass production while maintaining production volume and flexible customization.

“Freenity” was founded by a husband and wife. CEO and founder Ding-Xian Chen is on the left, holding a “topological structure” product. On the right is his wife, chief operating officer, Wei-Ying Chen, holding a designer-commissioned product.

Founder Ding-xian Chen, who has studied at Taiwan Tech from undergraduate to doctoral level, believes that 3D printing will be the core technology for the manufacturing industry over the next 10 to 20 years. It eliminates the need for further validation before large-scale production, allowing direct production after front-end verification.

Chen gave the example of badminton rackets, which require significant customization. He partnered with Victor Sports to produce 50,000 rackets in various specifications using 3D printing - far exceeding the typical few hundred pieces produced in conventional 3D printing. He also helped manufacturers develop limited-edition co-branded “front cover” badminton rackets, maximizing the customization capabilities of 3D printing.

“Freenity” was co-founded by a husband-and-wife team. CEO and founder Ding-Xian Chen are on the right, and on the left is his wife, COO Wei-Ying Chen, both holding the “front cover” badminton racket product.

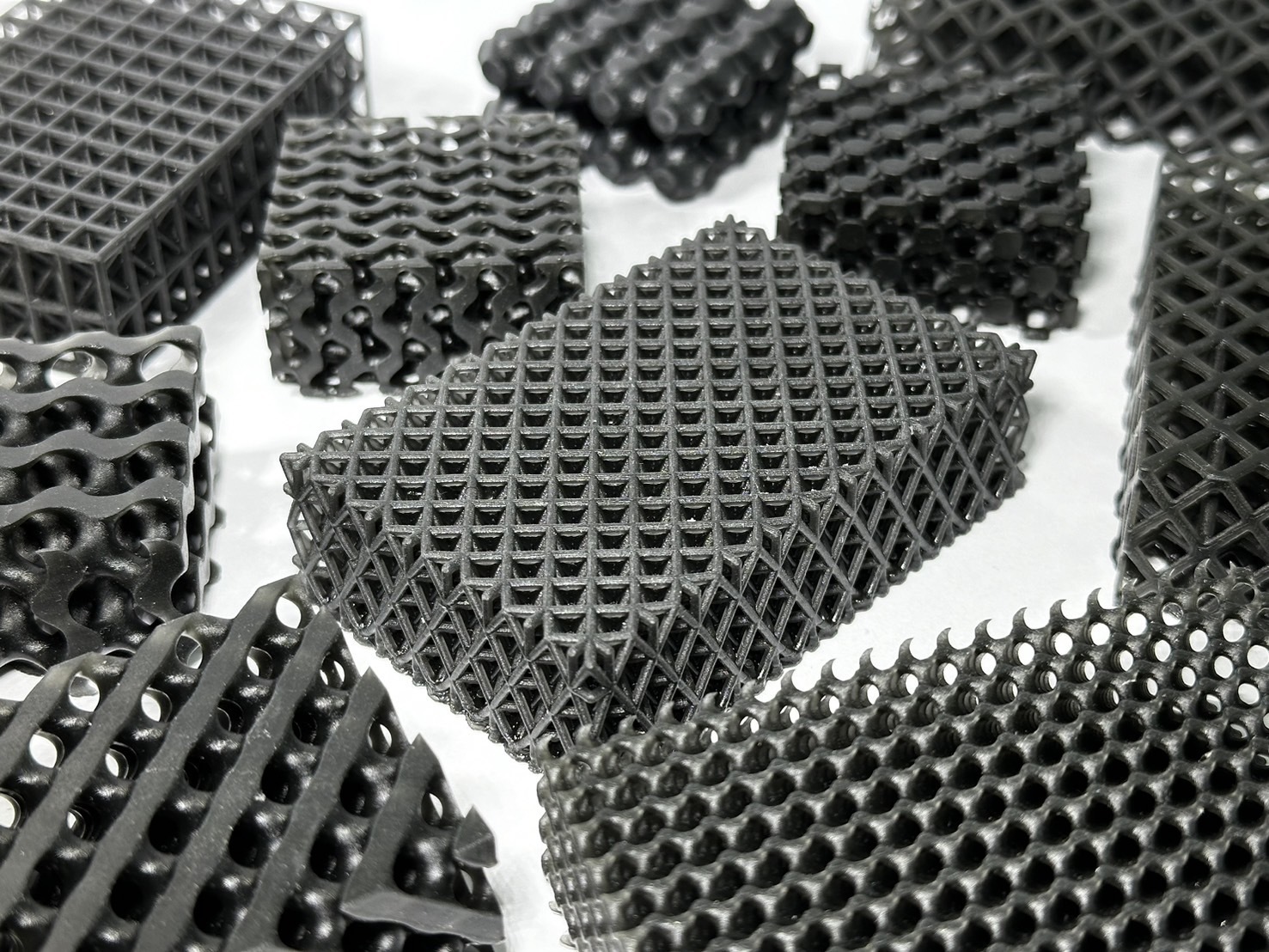

The varying hardness of the “topological structure” in 3D printing can help shoe manufacturers address foot pressure issues, allowing them to avoid making large-scale molds for every size, thus significantly reducing costs. This technology extends to educational tools and endoscope components in the medical field. It has also facilitated technical collaborations with research institutions, including Taiwan Tech, NTU, NCKU, NTHU, and YU, to ensure that the “end product” matches the intended design. Examples include medical and cosmetic products such as microneedles, microfluidic channels, and microlenses.

Founder Chen Ding-xian, who has studied at Taiwan Tech from undergraduate to doctoral level, believes that 3D printing will be the core technology for the manufacturing industry over the next 10 to 20 years.

Ding-Xian Chen stated that his expertise in 3D printing technology can meet various customer needs for textures and patterns, helping amateur designers bring their designs to life through direct 3D printing, thus fulfilling their dreams. The technology provides a one-stop production solution, effectively reducing product development risks. It also assists startups looking to launch products on crowdfunding platforms by addressing estimation errors, accurately calculating costs, obtaining secure pricing, and ensuring clear product pricing, ultimately protecting profit margins.

The startup “Freenity”, incubated by Taiwan Tech’s business incubation center, has become a mass-producible 3D printing company while maintaining production volume and flexible customization.

As a husband-and-wife entrepreneurial team, when ideas diverge, Wei-Ying Chen, who started multiple tutoring centers at the age of 21, offers valuable experience to help them navigate challenges over the past four years. Optimistic founder Ding-Xian Chen believes that “where there’s a will, there’s a way.” 3D printing has not only helped him realize his entrepreneurial dreams but also enabled him to help others fulfill their design aspirations.

He compares 3D printing to an airplane that carries everyone’s dreams, turning imaginative ideas into tangible realities. Additionally, he has leveraged his wife’s educational resources to promote 3D printing through classes, aiming to root this technology in communities. Beyond passing on experience, he hopes to help more people understand how “3D printing” a key aspect of Industry 4.0, can revolutionize manufacturing.

“Freenity” uses “topological structure” with varying hardness to help shoe manufacturers address foot pressure issues.